If you are a chef or outdoor adventure geek, finding the right kind of steel blade is very crucial and sometimes it is life’s savior too.

Crucible CPM steels are known for their hardness, toughness, edge retention, and excellent wear and tear resistivity. Their “S” lineup is very popular and in this article, I am going to talk about the two most famous “S” series steel types namely S30v and S35vn.

Let’s understand what I’m going to cover here…

- What are they?

- Their chemical composition.

- Their physical properties

- Similarities

- Differences

- Which one is best in which parameters?

So without further ado…

Let’s break it down…

Table of Contents

Does S30v Stainless Steel Good For A Knife?

S30V is the most popular steel type that was launched in 2001 and is still a first choice for many knife geeks. Earlier knife makers are not satisfied with the performance of BG42 steel.

They want something which has excellent toughness, better edge retention, and also has corrosion resistance properties. S30V steel is developed using a powder metallurgy process. It has some improved features than the BG42 which are:

- S30V comes with a finer carbide structure with improved toughness. This is possible by using a powder metallurgy process.

- It has better Edge retention capability over BG42. The percentage of Vanadium is increased in the microstructure of S30V which is a harder vanadium carbide that improved the wear-resistant property of S30V significantly.

- By increasing the percentage of Vanadium and reducing the Chromium carbide quality, S30V steel has better corrosion resistivity than the BG42 and 154CM.

But Steel manufacturers want something more tough steel than the S30V and this is achieved with the new and improved steel type that is CPM S35VN.

CPM S30v Or S30v Chemical Composition

CPM S30V comes with 1.45% carbon with is 0.05 percentage higher than the S35VN, this little chemical change creates a big difference in terms of the toughness of the steel.

4% Vanadium is helpful to enhance the wear resistivity and hardening of that steel, and the amount of Vanadium is 1% less in S35VN. S30V has 14% chromium content, and 2% Mobyldenum.

The Main Chemical Components In S30v

| Carbon | Chromium | Vanadium | Molybdenum |

| 1.45% | 14% | 4% | 2% |

It has some other carbides such as Nitrogen which is removed from the S35VN. All of these changes make S35VN better in some properties but S30V still has slightly better edge retention than the S35VN.

Advantages Of Using A Knife Based On S30v

- S30V has slightly better toughness than the BG42 but S35VN has slightly better in this property.

- S30V is slightly easier to sharpen than the S35VN.

- In terms of corrosion resistivity both steels perform the same.

Our Recommended Best Knives Based On S30v Steel

Best Seller

Spyderco Para Military Steel Blade With G-10 Handle

- Full Flat Grind.

- Made In the USA.

- 3.42″ Blade & 8.24″ Length

View the current price here

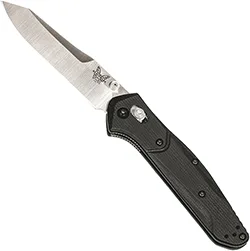

Top Pick

Benchmade 940 EDC Manual Opening And Closing

- Reversible, Lightweight, Locking Blades

- G10 Handle, G10 Handle

- Alloy Steel

View the current price here

Also Read: S30v Vs 154cm: Which Knife Is Best?

Does S35vn Good For A Knife?

S35VN was launched after 8 years of the launch of S30V with some improvements. Both the steels are developed by the Crucible. The word “N” on its name may be added because of Niobium. The structure of S30V is fine but S35VN comes with a finer grain structure than it.

This is the steel that is better in terms of machinability, easy to grind, and easy to polish. The S35VN has some advantages over the S30V and one of them is it is slightly better in toughness than the S30V.

CPM S35vn Or S35vn Chemical Composition

CPM S35VN comes with reduced vanadium and the addition of 1% Niobium in its chemical composition. Niobium makes the microstructure of S35VN more refine than the S30V.

S30V has some percentage of Nitrogen (0.2%) which is removed from the S35VN. All of these small changes make a significant improvement on some properties of S35VN over the S30V steel such as improving toughness, and machinability, but reduce the edge retention property of S35VN with respect to S30V.

The Main Chemical Components Of S35vn

| Carbon | Chromium | Molybdenum | Vanadium | Niobium | Nitrogen |

| 1.4 | 14 | 2 | 3 | 0.5 | – |

There are two identical things in both steel types which are:

- The heat treatment results are the same in most cases.

- Both have almost the same corrosion resistivity.

According to the Carta test results, the edge retention of S35VN is 17% lower as compared to S30V.

| Carta Test Results Performed By Bohler-Uddeholm |

| S30V- 149% S35VN- 132% |

Advantages Of Using A Knife Which Is Manufactured With S35vn Steel

- S35VN has excellent hardness, toughness, and edge retention properties.

- This is a steel type that is easy to grind and machine.

- This could be a great choice for hunting, survival training, fishing, in the kitchen, etc.

Best Seller

Zero tolerance 0450cf folding knife DLC coated S35VN

- 3.25” S35VN Edge plain blade

- The carbon handle with great strength is yet very light.

- Thumb ramp and pocket clip.

- Smooth opening.

View the current price here

S35vn Vs. S30v: Specifications

Steel Type

S35vn and S30v are developed to follow the exact same protocols. Both steels are byproducts of metallurgy powder. The little few changes in the S35vn chemical composition make it better in some paraments than the S30v such as its hardness, and toughness being improved but the edge retention capability is decreased to some extent.

Chemical Composition Comparison

| Carbon | Chromium | Vanadium | Molybdenum | |

| S30v | 1.45 | 14 | 4 | 2 |

| S35vn | 1.4 | 14 | 3 | 2 |

Edge Retention Comparison Between S30v And S35vn

The edge retention capability of S30v is around 149% and for S35vn it is only 132%. It means the S35vn edge retention capability is 17% less than the S30v.

The following results are based on the CATRA study performed by Bohler-Uddeholm.

Corrosion Resistivity Comparison

S35vn comes with great corrosion resistivity than the S30v. Chromium is a substance that is responsible to improve the corrosion resistivity of steel. Some tests proved that although the percentage of Chromium is the same in both the steel types, S35vn is likely superior to S30v in terms of corrosion resistance properties.

Hardness Comparison

The hardness of the S35vn is between 58 and 61 HRC and The hardness level of s30v according to Rockwell Hardness is between 58 and 61 HRC. Both the steels come with excellent hardness.

Toughness

S30v is hard steel which impacts its toughness. It has better hardness and corrosion resistivity but its toughness is not the same.

On the other hand, S35vn has a proper balance of toughness to the other qualities such as corrosion resistance and wear resistance. All three qualities of steel is the rear but it has a proper balance of toughness, hardness, and wear/tear resistance.

Sharpness

S35vn and S30v both the steels have a hardness between 58 and 61 which indicates that the hardness level of both the steels is almost the same.

Both steels are hard and as the rule says the harder the substance the more difficult it is to sharpen its edges.

Does s30v and S35vn Steels Rust?

Every stainless steel will rust if it is not taken care of properly. S30v and S35vn both have 14% of chromium which provides great corrosion resistivity to them.

Note: If you want to use your knife for a longer time without rusting then after using it just wipe it with a dry cloth will extend its life and prevent any rusting.

Which One Is Best Between S30v And S35vn?

I hope you are now in the situation of choosing the right steel type for your knife.

But, if you are still in a dilemma between S35vn and S30v then here, I’m going to clear your doubt in a very simple way.

As I’ve earlier mentioned that S35vn is an improved version of its predecessor S30v. They both have almost the same chemical composition with some minor changes such as Nitrogen being removed from S30v and 0.5 % Niobium being added to S35vn chemical composition.

Both steels have excellent corrosion resistance, wear resistance, and toughness. and the edge retention of the S30v is better than S35vn whereas S35vn has slightly better toughness than the S30v.