Whether you are a chef or a survival expert, having a knife with the best steel that can meet the need of your day-to-day life is very important.

If you are confused between S90v and M390 then look no further because I’ve listed every single detail about these two high-end steel variants with all the similarities and differences.

Let’s have a look at what I’m going to cover in this article…

- What are they?

- Their chemical composition.

- Their physical properties

- Similarities

- Differences

- Which one is best in which parameters?

So without further ado…

Let’s walk you through about S90v and M390…

Table of Contents

Does S90v Stainless Steel Good For A Knife?

S90V is also known as CPM-S90V or CPM-420V, these are the name of the same steel manufactured by the Crucible Industry. It was released around 1996 and is known as a high-wear-resistant steel blade. The steel has a 9% composition of Vanadium which makes it highly wear-resistant and has a better capability of edge retention in tough use.

This feature keeps this steel type apart from the M390.

Due to its better edge retention and wear-resistant properties, S90V is used in the making of high-end knives and several cutting tools.

CPM S90v or S90v Chemical Composition

S90v comes with a high percentage of Carbon and vanadium. Carbon adds hardness to the steel and the presence of vanadium makes it wear resistance and better edge retention even in tough use.

The Main Chemical Components Of S90v

| Carbon | Chromium | Molybdenum | Vanadium | Nitrogen |

| 2.3 | 14 | 1 | 9 | 0.1 |

The percentage of Vanadium is 9% in S90v which is almost 125% more than the M390. M390 has only 4% of Vanadium.

1% Molybdenum is for improving the wear resistivity of the S90V and 0.1% Nitrogen is added by replacing a few amounts of carbon for enhancing the corrosion resistivity of the blade without affecting the wear resistivity of it.

Advantages Of Using S90v Steel In Manufacturing A Knife

- S90V is not used as a common knife steel because of its very high wear resistivity.

- The knives made from S90V have longer edge retention properties, which make them an ideal choice for survival stuff, hiking, and hunting stuff.

- It is used in making Multi-tools and utility knives.

Best S90v Steel Knive In The Market

Best Seller

Benchmade 940-1 Manual Folding Knife

- Sharp 3.4″ plain edge blade

- ultra carbon fiber handle (lightweight and very strong).

- a rock-solid AXIS Locking mechanism

View the current price here

Does M390 Stainless Steel Good For Knife?

M390 project was an adjustment experiment in the traditional chemical composition of the powder metallurgy tool steel. M390 was developed in the late 80s with the vision to develop a new steel type with improved wear and tear resistance properties, that were missing in K190.

Developers at that time wants a highly wear-resistant metal, which was very much needed by the plastic industry at that time.

Since it would be used in plastic processing, that’s the reason toughness was not the primary concern for the developers.

Although M390 was developed by BOHLER-UDDENHOLM by using 3rd generation technology, using it for making knives was pushed by Latrobe steel in Pennsylvania, USA, and became a very popular knife-making steel in 2010.

M390 Chemical Composition

M390 has 1.9% of Carbon which provides toughness, and 0.7% of Silicon prevents bubble formation during the melting process and provides extra hardness to the steel.

0.3% Manganese provides strength, and 1% Molybdenum is for edge sharpening and also for the strength of the steel if treated at a high temperature.

The Main Chemical Components In M390

| Carbon | Molybdenum | Chromium | Vanadium |

| 1.9% | 1% | 20% | 4% |

Hardness and corrosion resistance are very important for steel and 20% of Chromium makes it possible. Steel must have wear resistance and 0.6% Tungsten makes M390 wear-resistant and also improves the toughness of the steel.

4% Vanadium is a substance that is mixed to enhance the wear resistivity of the knife and also ensure the correct distribution of the grains.

Advantages Of Using A Knife Based On M390

- M390 knives come with better edge retention than the S90v. Its edge retention capability is high due to the presence of 4% Vanadium and high carbide content.

- M390 is a highly tough steel that can bear beating, twisting, and blending very well.

- M390 is best in each and every parameter than the S90v.

Best Seller

Benchmade – Barrage 581 Knife With Aluminum Handle

- Blade Steel: M390 (60-62 HRC)

- Drop Point Knife with Satin finish

- Weight: 5.20oz. (147.42g)

View the current price here

Also Read: M390 Vs. S35vn: Similarities & Differences

M390 Vs. S90V: Specifications

Hardness Of The Steel

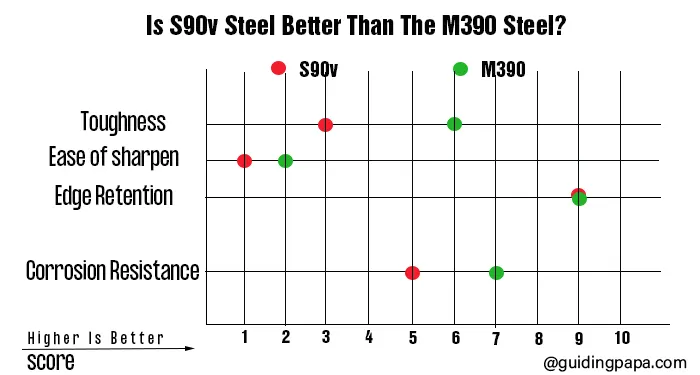

According to the Rockwell test results, the hardness of M390 is measured between 60 and 62 HRC which is between 57 and 59 HRC for S90v. The Rockwell test clearly stated that M390 has better hardness than the S90v.

Toughness

Toughness is Important for steel to prevent chips and total failure, which could be due to twisting, torsion, impact, etc. The toughness of the M390 is better than S90v.

Sharpening And Edge Retention Property

Some steels are easy to sharpen but others are very difficult to grind and sharpen. S90V is also the same kind of steel type.

M390 is much easier to sharpen and S90v takes some time in sharpening but the edge retention is better in S90v than the M390.

Chemical Composition Comparison

| Carbon% | Chromium% | Vanadium% | Molybdenum% | |

| S90v | 2.3 | 14 | 9 | 1 |

| M390 | 1.9 | 20 | 4 | 1 |

Rusting Nature

Every stainless steel will rust if it is not taken care of properly. S90v has 14% of chromium whereas M390 has 20% which provides great corrosion resistivity to them.

Note: If you want to use your knife for a longer time without rusting then after using it just wipe it with a dry cloth will extend its life and prevent any rusting.

Some Major Differences Between M390 And S90v

- M390 is much easier to sharpen than the S90v.

- S90v has better edge retention than the M390.

- M390 steel is harder than the S90v.

- M390 is tougher than the S90v.

Also Read: S30v Vs. M390: Similarities & Differences

Which One Is Best For Me Between S90v And M390?

Both the steel is premium and have some good features and some bad.

Go With S90v For

- Excellence edge retention.

- Good corrosion resistance

- Good toughness.

Go With M390 For

- This is the best steel for knife making.

- Best in every parameter.

- Excellent corrosion resistance.

- Excellent hardness and toughness.

- Much easier to sharpen.

- Good edge retention.