If you are looking for the best knife either for your kitchen, survival, or outdoor adventure trip, choosing the right steel blade is very crucial. Today we are going to discuss S30v vs. M390. Earlier we compared S30v with 154cm, S90v, and S35vn. You can also check them out if, interested.

Let’s understand what we are going to discuss in this article about these two most popular steel types…

- What are they?

- Their chemical composition and differences.

- Specifications

- Similarities

- Differences

- Which Steel type is best in which condition?

- Which one is best suited for you?

So without further ado…

Let’s compare them and understand what are the good things about the steel variant.

Table of Contents

S30v Vs. M390: Which One Is Best?

Does S30v Stainless Steel Good For A Knife?

S30V is an improved version of steel from these previously used steel types which are 440C, 154CM, S60V, and S90V. S30V was released in 2001 by Crucible and soon became very popular.

The previously developed steel types are good but have some limitations. The quality of S30V is better than the previously used steel named BG42.

S30V is a stainless steel due to the 14% of Chromium. This is a premium grade steel that is expensive too and used in making cutting tools, making knives, hunting and outdoor equipment, etc.

CPM S30v Or S30v Chemical Composition

In the formation of S30V steel, the company reduced the percentage of carbon and vanadium which resulted in improved toughness and grindability in the steel.

There is one main reason behind adding 4% Vanadium in the formation of S30V is increasing the wear resistivity.

The Main Chemical Components In S30v

| Carbon | Chromium | Vanadium | Molybdenum |

| 1.45% | 14% | 4% | 2% |

The above-mentioned chemical components are common, and apart from them there is 0.2 Nitrogen is added which increases the wear resistivity of the steel and also improves hardness during heat treatment.

Let’s have a look at all the additional chemical components that are added to this steel physical structure.

| Nitrogen | 0.2% | For edge retention. |

| Manganese | 0.5% | for hardness and bitterness. |

| Silicon | 0.5% | It also improves the strength of the steel. |

| Phosphorus | 0.03% | It also improve the strength of the steel. |

| Sulfur | 0.03% | Improve machinability. |

Advantages Of Using A Knife Based On S30v

- S30V comes with a hardness rating of 61HRC, which is good for edge retention.

- 14% Chromium makes it highly corrosion-resistant steel.

- The toughness of S30V is somewhere equal to or better than the 440C and D2 steel types.

- You don’t need to sharpen it frequently because this is a hard steel that has excellent edge retention capability.

Our Recommended Best S30v Knives In The Market

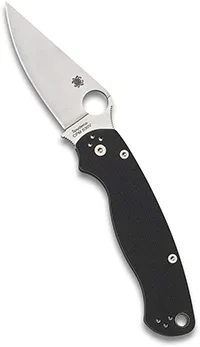

Best Seller

Spyderco Para Military Steel Blade With G-10 Handle

- Full Flat Grind.

- Made In the USA.

- 3.42″ Blade & 8.24″ Length

View the current price here

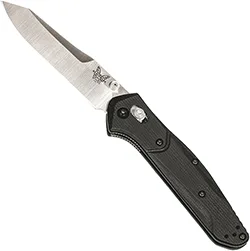

Top Pick

Benchmade 940 EDC Manual Opening And Closing

- Reversible, Lightweight, Locking Blades

- G10 Handle, G10 Handle

- Alloy Steel

View the current price here

Is M390 Stainless Steel Good For Knife?

M390 is not an ordinary steel type and you won’t see an M390 steel blade on a cheap Walmart ordinary knife. What makes it different from the other steel types is incredible edge retention and high wear/corrosion resistivity.

It was developed by an Australian steelmaker company BOHLER-UDDENHOLM. Initially, it was developed for making jet engine parts and for ball bearings due to its high performance but some manufacturers also use this steel in making highly wear/corrosion-resistant knives.

M390 Chemical Composition

In the 80s the powder metallurgy method is very common in making steels and M390 is also one result of this process. Let’s have a look at some common chemical substances:

M390 contains 1.9% C, 1%M, 4% V, and 20% Cr. Carbon is responsible for improving the toughness of steel, Molybdenum helps in maintaining the strength of a knife, and Vanadium ensures that all the added grains distribute evenly and improve the wear resistivity of a knife.

The Main Chemical Components In M390

| Carbon | Molybdenum | Chromium | Vanadium |

| 1.9% | 1% | 20% | 4% |

Apart from these main components it also has Tungsten (0.6%), Manganese (0.3%), and Silicon (0.7%). All of these elements play an important role in making this steel highly sharp while maintaining the shape of its edge and highly wear and corrosion-resistant.

Advantages Of Using A Knife Based On M390

- M390 knives come with better corrosion resistance than the S30v.

- M390 is a hard steel compared to S30V.

- It has more stainless steel properties than S30V because of the presence of 20% Cr.

Disadvantages Of M390

- It is a very difficult and time-consuming process of sharpening its edge.

- It is an expensive steel blade for a knife.

Best M390 Knives Right Now

Best Seller

Benchmade – Barrage 581 Knife With Aluminum Handle

- Blade Steel: M390 (60-62 HRC)

- Drop Point Knife with Satin finish

- Weight: 5.20oz. (147.42g)

View the current price here

M390 Vs. S30v: Specifications

Hardness Of The Steel

The hardness between 60 and 62 HRC is pretty high for a steel blade that is used in knife making. S30v comes with a hardness score between 58 and 61 HRC.

Toughness

As per the hardness results, S30v has more excellent toughness than the M390. We can clearly understand the hardness test result of both steels. Steel which is harder than the other steel type could not be that efficient in toughness, but some exceptions are also there.

Sharpening And Edge Retention Property

M390 and S30v both the steel variants have the same amount of Vanadium and Chromium carbide. Vanadium is a high-hardness carbide and the majority of the chromium carbide is a low-hardness carbide. Chromium carbide is a larger amount than Vanadium in the chemical composition of Powder Metallurgy Steel which limits its toughness.

It means both M390 and S30v are soft steel and easy to sharpen. Some test shows that the M390 has slightly better edge retention than the S30v.

Corrosion And Wear Resistance

The corrosion resistance test shows that M390 is slightly better than S30v. The percentage of chromium apart from Nitrogen and Molybdenum controls the corrosion resistance property of steel.

Chemical Composition Comparison

| Carbon% | Chromium% | Vanadium% | Molybdenum% | |

| S30v | 1.45 | 14 | 4 | 2 |

| M390 | 1.9 | 14 | 4 | 1 |

Does S30v And S90v Steel Rust?

Both steel types are stainless steel because both of them have 14% Chromium which is responsible for the stainless steel property of a steel type. It means both steel types are rust-free.

Note: To ensure that your knife remains rust-free for a long period just wipe it with a dry cloth after using it.

Differences Between S30v And M390

- M390 steel has much better wear resistance than the S30v.

- M390 edge retention capability is better than the S30v.

- S30v is much easier to sharpen than the M390.

Which One Is Best Between S30v and M390?

Many knife owners have a common doubt about these two steel varieties which is.

Would the M390 steel be an obvious choice over the S30V and why or why not?

M390 has some qualities that make it better than the s30v which are:

1. M390 is a newer and improved prototype of super steel than the S30v.

2. M390 has better edge retention properties than the S30v.

3. The M390 has better abrasion resistivity than the S30v.

These qualities make it a perfect choice for knife lovers and worth the extra money.

Reasons to choose s30v over M390:

1. This was the first super steel type which is used for knife manufacturing.

2. S30v is much easier to sharpen than the M390.

3. The S30v will cost you much cheaper than the M390.

Both the steel is best in terms of wear/tear resistance, toughness, and edge retention but M390 is way better in most of the parameters. Choose any one of them according to what matters to you most.