Crucible “S” series steel blades are very popular but also confused buyers that which one offers better edge retention, toughness, wear, and corrosion resistance.

Earlier we compared S110v with Maxamet and S30v. Check out them also.

Today I’m going to compare S90v with S110v. If you are confused between them then look no further as here, I’m going to discuss every single detail with similarities and differences so that you can choose the right steel brand for your knife blade.

Let’s have a look at what I’m going to discuss in this article…

- What are they?

- Their chemical composition and differences.

- Specifications

- Similarities

- Differences

- Which Steel type is best in which condition?

- Which one is best suited for you?

So further ado…

Let me walk you through this in-depth analysis.

Table of Contents

S90v Vs S110: Which Steel Is Best?

Does S90v Stainless Steel Good For A Knife?

S90v or CPM S90v was initially known as CPM-440 and was released in 1995. S90v is made using the Particle Metallurgy process. Initially, it was designed as tool steel and named CPM-440 and was patented in 1996.

S90v is an expensive version of steel that is used to design some high-end knives. 14% Chromium listed S90v in the category of stainless steel. This is a kind of steel that keeps its edges sharp for a longer period of time and doesn’t require frequent sharpening.

The S90v variant of steel is popular for making bearings, slitters, cutlery, outdoor hiking, etc.

CPM S90v or S90v Chemical Composition

S90v has some huge changes in its chemical composition if we compare it with S110v. S90v has 2.3% Carbon which is approx 21.5% lower than the S110v which has 2.8% of Carbon.

Carbon makes steel hard and also enhances its ability to bear any wear/tear. 14% Chromium is ideal in both steel types. There is a huge effect of Chromium in steel processing as it enhances the tensile strength, toughness, hardness, and edge retention property.

The Main Chemical Components Of S90v

| Carbon | Chromium | Molybdenum | Vanadium | Nitrogen |

| 2.3 | 14 | 1 | 8.75-9 | 0.1 |

Vanadium also plays a very important role to make steel tough, wear-resistant, and improving its strength. The percentage of Vanadium is 9% in S90v which is the same as we’ve seen in the S110v.

1% Molybdenum and 0.03% sulfur enhances the machinability, and strength of the steel. Other substances which are added to improve the toughness, strength, and hardness of the S90v steel are 0.5% Silicon and Manganese, 0.40% Tungsten, and 0.03% of Phosphorus.

Advantages Of Using S90v Steel in Manufacturing A Knife

- S90v is a tough steel blade.

- The knife made with S90v remains sharp for a longer period of time.

- This is very hard and durable steel because of the 9% of Vanadium.

Recommended Best S90v Steel knife In The Market

Best Seller

Benchmade 940-1 Manual Folding Knife

- Sharp 3.4″ plain edge blade

- ultra carbon fiber handle (lightweight and very strong).

- a rock-solid AXIS Locking mechanism.

View the current price here

Also Read: S30v Vs. S90v: Differences & Similarities

Does S110v Steel Is Good For A Knife?

S110V is developed by Crucible and is a very popular steel type since it launched. Its chemical composition makes it highly wear/corrosion resistant, tough, and ductile. Its two versions have been launched. The first one which is known as Patent was launched in 2006 and the latter was launched in 2010 and is known as Final.

Earlier we have already have S90V, S30V, and S125V, but what makes S110V different from them is the addition of Niobium, which added a highly resistant property to the steel.

S110v (Patent Version) Chemical Composition

| Carbon | Chromium | Vanadium | Molybdenum | Niobium | Cobalt |

| 2.8 | 14 | 9 | 3.5 | 3.5 | 2 |

The percentage of carbon in the S110V patent version is 2.8% and is 0.5 high when compared to S90v.

The S110V patent version comes with Niobium, and it has a little bit high Molybdenum than the S90V. Chromium and Molybdenum combined to make steel highly corrosion-resistant.

The addition of Niobium whose carbide size is small helps in reducing the size of Chromium and Vanadium and this is the reason the structure of carbide in S110V is finer and has more carbide than the S90V.

Have a look at the Chemical Composition Of The Final Version Of S110v

| Carbon | Chromium | Molybdenum | Vanadium | Niobium | Cobalt |

| 2.8 | 15.25 | 2.25 | 9 | 3 | 2.5 |

The Final version of S110V comes with significant changes in the chemical composition. The percentage of Chromium is increased but the percentage of Molybdenum is decreased. All of these changes make S110V highly wear & corrosion resistant, and at the same time provide ductility and toughness to the steel.

The structure of the carbide is finer in S110v than in the S90v which is impressive and provides the toughness of the steel.

Advantages Of Using S110v In Knife Making

- Decent edge retention.

- High hardness and corrosion resistance.

Recommended Best S110v Kinfe In The Market

Best Seller

Spyderco Para Military 2 Signature Midnight Blue Knife

- 3.42″ CPM S110V Steel Blade

- Durable G10 Handle.

- Weight: 5 Ounces

- The Para Military 2 features extreme strength, reliability, ease of use of our patented Compression Lock mechanism, and versatility of a 4-position pocket clip.

View the current price here

S110v Vs. S90v: Specifications

Hardness Comparison

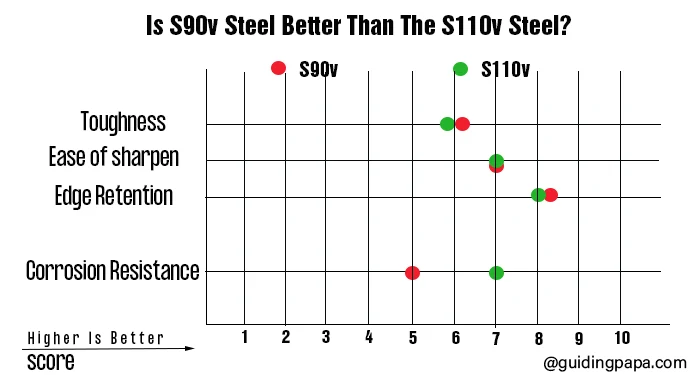

To measure the hardness of both steel types we consider the test results of the Rockwell Scale. According to the Rockwell test, the hardness of S90v is between 57 and 59 HRC, and it goes max up to 63.5 HRC for the S110v variant.

Although both the steel come with a high level of hardness.

Toughness Comparison

Many heat treatment tests stated that the S90v has greater toughness than the S110v due to the lower carbide content in S90v than the S110v.

Wear & Corrosion Resistance Comparison

Due to the modification of Molybdenum and Niobium, there is a significant upgrade in the wear and corrosion resistance of the S110v over the S90v. However, some test results show identical wear resistivity between them.

Edge Retention And Sharpening Comparison

The S110v comes with decent Edge retention but surprisingly underperforms when compared to the S90v. This totally surprised me and I think this is due to the smaller size of carbide in the S110v than in the S90v.

Both the steel blades are easier to sharpen and take almost the same time in sharpening.

Chemical Composition Comparison

| C | Cr | Mo | V | Nb | Co | |

| S90v | 2.3 | 14 | 1 | 9 | – | – |

| S110v | 2.3 | 14 | 2 | 4 | 3 | 2.5 |

Does S90v And S110v Steel Rust?

Every stainless steel will rust if it is not taken care of properly. S110v and S90v both have 14% of chromium which provides great corrosion resistivity to them.

Note: If you want to use your knife for a longer time without rusting then after using it just wipe it with a dry cloth will extend its life and prevent any rusting.

Also Read: S90v Vs M390:Differences & Similarities

Conclusion: Which One Is Best Between S90v And S110v?

S110v steel comes with some improvements. If you want the answer to the question…

Which Steel Is Best Between S90v And S110v?

The answer is definitely S110v. But I loved both S90v and S110v for high edge retention and corrosion resistance. Both types of steel are tough and are good as kitchen tools, hiking, and survival knife.