If you want the best knife either for your day-to-day kitchen work or for hiking or camping then it depends on many factors such as the type of blade, its material, processing methods, and much more.

There are lots of blade steel varieties available in the market, which can definitely confuse you if you don’t have proper knowledge about them.

In the series of knife steel comparisons, today we are comparing the two most famous steel types namely Vg10 and 154cm.

Let’s have a look at what we are going to discuss in this article to clarify every single doubt of yours regarding these two steel variants.

- Brief history and origin of steel.

- What they are?

- Chemical composition.

- Hardness

- Edge retention property.

- Uses

So, without wasting much time of yours, let’s begin…

Table of Contents

Does VG10 Stainless Steel Good For Knife?

VG10 is one of the stainless steel types based in Japan. The VG10 is the most popular steel grade to manufacture knives and other sharp tools in the cutlery industry.

What Is VG10?

The word G in VG10 stands for “Gold” which means Quality like Gold. VG10 is the most popular and high-end Japanese stainless steel that was designed by Takefu Special Steel Co. Ltd.

VG10 steel Chemical Composition

VG10 steel is made of several different components, one of them and the most commonly used component is carbon. The Carbon percentage is 1% in this steel, which is responsible to provide hardness to the object made by VG10. Carbon is also helpful to make the objects wear and tear-resistant if added in a defined ratio.

The second chemical element which is used in VG10 steel is Chromium. 15% of this chemical substance provides tensile strength, and also improves the wear and tear resistivity of the knife made by VG10.

| Carbon | Chromium | Molybdenum | Vanadium | Cobalt | Manganese | Phosphorus |

| 0.95-1.05 | 14.50-15.50 | 0.90-1.20 | 0.10-0.30 | 1.30-1.50 | 0.50 | 0.03 |

To increase, the hardness and bitterness of the knives, 0.5% of Manganese is also added to the VG10 steel chemical composition. The knives based on VG10 get strength from Phosphorus, which is mixed in 0.3% in the chemical composition.

The VG10 knives are good in strength and machinability due to the presence of 1% Molybdenum. 0.25% Vanadium and 1.5% Cobalt are also a part of its chemical composition, they together improve the hardenability and make the knife wear and tear-resistant.

The VG10 steel hardness is HRC60, which is comparable with its rival 154cm. The knife made by VG10 with HRC60 has good edge retention properties. 15% Chromium makes this steel corrosion and wear-resistant.

If we compare VG10 with 154cm then the percentage of Carbon is almost the same but in 154cm the percentage of Chromium is less. The edge retention on 154cm is better due to the presence of silicon and sulfur which are missing on VG10.

I found that the VG10 steel is hard and easy to sharpen in less time. It means the time that is going to be wasted in sharpening the knife based on VG10 steel would be minimal.

Advantages Of Using A Knife Based On VG10 Steel

- VG10 is high-end steel and the knives made with this are most popular in Japan.

- The knives made with VG10 come with decent edge retention, wear, and corrosion resistance as well.

- VG10 knives are easy to sharpen and take less time in sharpening than the 154CM.

Best VG10 Knives In The Market

Best Seller

Chef Knife, imarku 8 inch Kitchen Knife Premium Sharp Cooking Knife VG10 Stainless Steel

View the current price here

Does 154CM Good For A Knife?

154cm has been high-end steel for a long ago. 154cm steel is one of the best materials for knife manufacturing which is manufactured in the USA by the Crucible Industry. 154cm is a modified form of 440c which is Martensitic stainless steel.

The formation of 154cm started with the addition of Molybdenum in 440c. Steel was developed in 1970 and used to make Jet engine turbine components at that time.

The steel is known for its hardness, and wear resistivity and enhances the corrosion resistivity as well. Unlike S30v, this is not a kind of steel made with powder steel. Now steel is very popular to manufacture cutlery and knife blades.

154cm Chemical Composition

154cm is made of a combination of different components, one of them is Carbon. Carbon is known to improve the hardness of steel and it also makes steel wear and corrosion-resistant. But it will reduce the strength of the steel if added in excess quantity. The carbon percentage in 154cm steel is 1.05%.

Nobody wants that the knife he is using loses its edge retention again and again and needs frequent sharpening. A chemical substance namely Chromium improves the strength and edge retention property of the steel and is also known for improving the wear and tear resistivity of the knife. The Percentage of Chromium in 154cm is 14%.

Don’t be confused between the 154CM and CPM154 both are different. CPM154 is a powder metallurgy steel whereas 154CM is not.

The Main Chemical Components In 154cm

| Carbon | Chromium | Manganese | Molybdenum | Vanadium | Silicon | Sulfur | Phosphorus |

| 1.05% | 13.50-14% | 0.50% | 4% | 0-0.40% | 0.30-0.80% | 0.03% | 0.03% |

Other chemical substances which are used to improve the strength of the steel are used in 154cm: Silicon 0.30%, and phosphorus 0.03%.

To improve the machinability of the steel some other chemicals are used. Here I’ve mentioned the percentage of these chemical components in 154cm which is Molybdenum 4%, and Sulfer 0.03%.

To improve the hardness and bitterness Manganese 0.5%, Vanadium 4%, and Tungsten 0.4% are mixed in the 154cm.

Advantages Of Using 154cm Based Knife

- Its HRC value is between 58 and 61 which makes it harder steel than other stainless steel varieties.

- It can retain its sharpness for a longer time.

- It is less expensive than the other most popular steel types.

- This is a type of steel used in survival knives.

Best 154cm Steel Knife In The Market

Best Seller

Benchmade Mini Barrage 585 EDC Knife

- The 154CM stainless steel blade.

- Stainless Steel Handle.

- Satin Finish

View the current price here

VG10 Vs 154CM: Specifications

Chemical Composition

The chemical composition of N690 and VG10 is mentioned below in table…

| C | Cr | Mo | Co | V | Manganese | |

| VG10 | 0.95-1.05 | 14.50-15.50 | 0.90-1.20 | 1.30-1.50 | 0.10-0.30 | 0.50 |

| 154CM | 1.05 | 13.50-14 | 4 | 0 | 0-0.40 | 0.50 |

Chemical composition of 154CM and VG10

Hardness Comparison

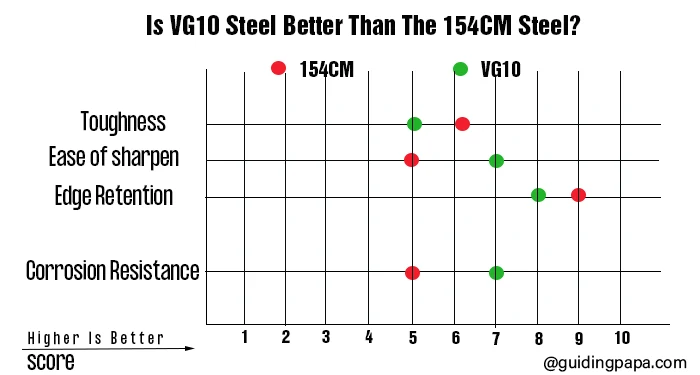

We consider the data of Rockwell for the measurement of the hardness and according to Rockwell data, the hardness of 154CM is Between 60 and 61 HCR. The hardness of VG10 is between 56 and 60 HRC.

The Rockwell hardness test clearly stated that 154CM is harder than the VG10.

Edge Retention & Sharpening Comparision

The Vg10 offers a better sharpening blade than the 154CM. It takes very less time in sharpening but required frequent sharpening.

Whereas 154CM edge retention is slightly better than the VG10. This is hard steel which is why it offers better edge retention but this steel is hard to sharpen and takes lots of time in sharpening.

Wear & Corrosion Resistance

VG10 offers better corrosion resistance than the 154CM, but the 154CM is better wear resistance than the VG10. The percentage of Vanadium is a bit high and this is the reason for its better wear resistivity.

Toughness

The toughness of the steel which is hard is slightly less. The percentage of carbon and chromium in both the steel blade is almost the same which mean both the steel come with decent toughness.

Does VG10 and 154cm Steels Rust?

Every stainless steel will rust if it is not taken care of properly. VG10 and 154cm both have 14% of chromium which provides great corrosion resistivity to them.

Note: If you want to use your knife for a longer time without rusting then after using it just wipe it with a dry cloth will extend its life and prevent any rusting.

Which One Is Best Between VG10 And 154CM?

After reading the whole article, I hope you are in the condition of choosing the right steel blade for your knife. If you are still in confusion about them then let me clear it up in a nutshell.

Both the steel types come with good edge retention but some cutting tests prove that 154CM has better edge retention than the VG10. VG10 is slightly better in edge sharpening and takes less time in sharpening than the 154CM.

VG10 is better in Corrosion resistance and 154CM is better in wear resistance. Both the steel come with decent toughness.

Choose VG10 If You Want

- Better corossion resistance.

- Ease of sharpening.

Choose 154CM If You Want

- A tough steel blade.

- Better edge retention.