Knives are very important for any survival or hunting activities. Outdoor hunting and camping need a knife with a top-quality steel blade. You need a sharp knife with better edge retention to cut meat, fish, and vegetables, cut wood for a fire, and make shelter.

They are also very important tools in the kitchen and can be used for a variety of purposes such as cutting, chopping, slicing, peeling, etc.

We have earlier compared S110v with S30v and S90v. You can check out this detailed comparison too, if interested.

Today we are going to compare the two most popular steel types which are Maxamet Vs S110v. We have tested both the Maxamet and S110v knives to see which one is better for you.

Before we proceed further, let’s understand in which parameters we are going to compare them to conclude a feasible result.

- What are they?

- Their chemical composition and differences.

- Specifications

- Similarities

- Differences

- Which Steel type is best in which condition?

- Which one is best suited for you?

Table of Contents

Maxamet Vs. S110v: Differences & Similarities

Maxamet

What is Maxamet steel?

Maxamet is a type of steel developed by Carpenter Technology Co. based in Philadelphia one of the largest cities in Pennsylvania USA.

Carpenter Technology is one of the leading suppliers of high-performance steel worldwide. This is middle-ground steel between the high-speed steel and cemented carbide.

Maxamet is claimed to be a steel blade with improved hardness & wear resistance than the other high-speed steels and is tougher than the cemented carbide.

Does Maxamet Steel Is Good?

Definitely yes, Maxamet is super hard high-speed steel whose hardness is above 65HRD. Maxamet has a high amount of tungsten which improves its hardness and makes it highly wear-resistant.

This is not stainless steel because the percentage of chromium is less than 14%. That’s the reason it has poor corroding resistivity than the S110v.

The knife is not suitable to use in a humid climate, because it will rust and corrode soon. Otherwise, this is the steel of the EDC knife.

Maxamet Chemical Composition

Maxamet is not stainless steel, because it has a very low percentage of Chromium which is only 4.75%. But this is a super hard and high wear resistance steel type due to the high amount of Tungsten and Vanadium.

Let’s have a look at its chemical composition:

| Carbon | Chromium | Tungsten | Vanadium | Cobalt | Manganese | Silicon | Sulfur |

| 2.15% | 4.75% | 13% | 6% | 6% | 0.3% | 0.25% | 0.07% |

The percentage of Carbon in Maxamet is only 2.15% which is almost 0.65% less than the S110v. Carbon is responsible for improving the hardness, wear, and corrosion resistivity of the steel.

Maxamet steel is not stainless steel because it has only 4.75% Chromium which is less than 14% of the eligible criterion. Chromium is responsible for improving edge retention, and corrosion/wear resistivity.

Maxamet has better hardness, cutting efficiency, and better wear resistance than the S110v. 13% Tungsten makes it possible.

6% Vanadium is almost 3% less in Maxamet than the S110v. It improves hardness and wear resistivity.

Maxamet has 4% more Cobalt than the S110v which triggers the effect of other elements of the composition.

Other available substances are Manganese (enhance hardness, sharpness retention, and bitterness) Silicon (improve toughness and strength), and Sulfur (improve machinability).

Advantages Of Using Maxamet Blade In Knife Making

- One of the strongest steel for knife making.

- It has better edge retention than the S110v.

- Its hardness level is higher than some other top steel variants.

- You will get a high-wear resistance steel blade here.

Disadvantages Of Maxamet Blade In Knife Making

- This is not stainless steel and pronto rust, if not cared for properly.

- This is a hard steel that’s the reason for its low toughness.

- Sharpening of Maxamet is difficult and takes more time than the S110v.

Best Maxamet Knives In The Market

Best Seller

Spyderco Native 5 Signature Folder Knife With Maxamet Steel Blade

- Lightweight, Locking

- Fiberglass Reinforced Nylon Handle

- Alloy Steel Maxamet Balde

View the current price here

S110v

What is S110v Steel?

S110v is a high alloy martensitic stainless steel that is made by the process called CPM. The word CPM stands for the Crucible Particle Metallurgy process. This is also known as CPM S110v.

S110v is an upgraded version of S90v having all its properties with improved wear and corrosion resistivity. The S110v is best for kitchen cutlery uses.

Is S110v Steel Is Good For a Knife?

S110v is also developed by Crucible Industry and is a powder metallurgy tool steel. S110v was developed for plastic injection applications that require high wear and corrosion resistance steel.

The S110v steel was patented in 2006 by its inventors Alojz, Andrzej, and Maria Sawford. This is a premium tier tool steel and is today widely used in making industrial knives, food tools, slitters, screws, etc.

S110v has two versions. One is patent and the other is final.

S110v (Patent Version) Chemical Composition

| Carbon | Chromium | Vanadium | Molybdenum | Niobium | Cobalt |

| 2.8 | 14 | 9 | 3.5 | 3.5 | 2 |

The S110v patent version has 2.8% of carbon which is 0.65% high when compared to Maxamet. Carbon makes steel hard and also enhances the wear/corrosion resistivity of a steel blade but it can reduce the strength of the steel when added to a large quality.

There is a huge difference in the percentage of Chromium in both the steel type which is 14% in S110v and only 4.75% in Maxamet, and the percentage of Vanadium is 3% more in S110v than the Maxamet. Vanadium and Chromium are responsible for getting high wear and corrosion resistance in the steel but, balancing their used quantity is challenging to achieve the desired wear and corrosion resistance property.

One of the major changes you will see in S110v is the addition of Niobium which is missing on Maxamet.

Have a look at the Chemical Composition Of The Final Version Of S110v

| Carbon | Chromium | Molybdenum | Vanadium | Niobium | Cobalt |

| 2.8 | 15.25 | 2.25 | 9 | 3 | 2.5 |

The final version of S110v was launched in 2010 with some changes in the chemical composition of its earlier version. S110v is an upgraded version of steel in terms of corrosion and wear resistance. The new version was introduced to fix the issue with gas atomization, forging, and annealing of the steel.

The structure of the carbide is quite different in S110v than in the Maxamet which is impressive and provides the toughness of the steel. Cobalt is a very useful substance that helps to austenite the steel at a high temperature which is higher in Maxamet than the S110v.

Advantages Of Using S110v In Knife Making

- Better Edge Retention.

- Better wear and corrosion resistance.

Applications Of S110v

- S110v is very popular to produce compounding machine components such as barrels, barrel lines, screws, etc.

- For manufacturing commercial knives, slitters, and circular cutters.

- In Food and chemical industries for food packing and rolling components.

Best S110v Knife In The Market

Best Seller

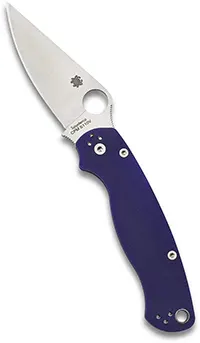

Spyderco Para Military 2 Signature Midnight Blue Knife

- 3.42″ CPM S110V Steel Blade

- Durable G10 Handle.

- Weight: 5 Ounces

- The Para Military 2 features extreme strength, reliability, ease of use of our patented Compression Lock mechanism, and versatility of a 4-position pocket clip.

View the current price here

Comparison Of Steel Properties Maxamet Or S110v

Hardness Comparison

The hardness of the steel defines the ability of the steel to resist the penetration of an object. The harder the steel is, the more difficult it will be for an object to penetrate it. The hardness also defines how hard a tool is made to ensure that it can withstand the pressure it may be subjected to during use.

Let’s see which steel has better hardness:

What is the hardness(HRC) of Maxamet steel?

We are using the test result of Cartech, and according to their test results, the hardness of Maxamet steel is between 67 to 70, and the maximum HRC rating goes up to 70 HRC which is the highest rating for any type of steel to achieve.

In terms of hardness, edge retention, and wear resistance Maxamet has no competition.

What is the hardness(HRC) Of S110v?

Rockwell test shows that the hardness rating of S110v goes maximum up to 63.5 HRC. This result is also good but S110v is not as hard as Maxamet steel is.

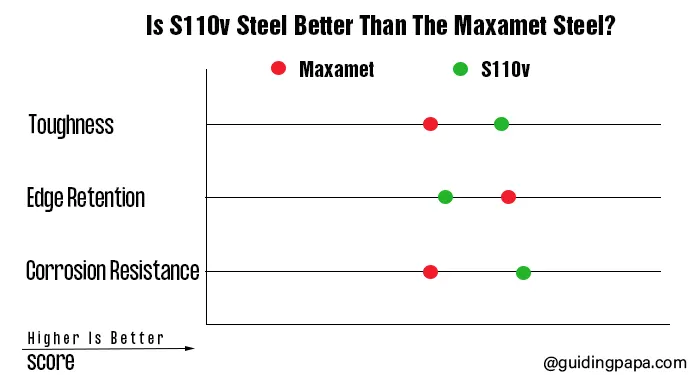

Toughness Test

The fact is that the steel whose hardness is high, its toughness is proportionally low. According to this rule, Maxamet hardness is higher than the S110v steel, which makes it less tough than the S110v.

Hard steel pron to chipped, and brittle, but this is not the case with Maxamet, it is relatively tough but not as much as S110v is.

Wear Resistance Test

In terms of wear resistivity, hard steel wins the battle, which means Maxamet has more wear resistance than the S110v.

Corrosion & Rust Resistance Test

Unlike S110v, Maxamet is not stainless steel, which means it is less corrosion resistant and can easily rust, than the S110v.

In terms of corrosion resistivity and rust resistance properties, S110v is way better than the Maxamet steel.

Edge Retention & Ease Of Sharpening Test

Tough steel comes with better edge retention properties, that’s the reason that Maxamet has better edge retention than the S110v.

In terms of ease of sharpening test, S110v is way better and takes less time in sharpening than the Maxamet.

But, it doesn’t mean that it is tough to sharpen Maxamet, you can shape this steel blade using diamond, and some other modern sharpening systems without much effort, but sharpening S110v is much easier and faster than the Maxamet.

Machinability Test

A substance called Sulfur is responsible for better machinability which makes steel easy to process. Maxamet has 0.23% sulfur which improves its machinability. Unfortunately sulfur is missing in the chemical composition of S110v.

Chemical Composition Comparison Chart

| Substances | Carbon | Vanadium | Chromium | Tungsten | Molybdenum | Niobium | Silicon | Cobalt | Sulfur | Manganese |

| Maxamet | 2.15% | 6% | 4.75% | 13% | – | – | 0.25% | 6% | 0.07% | 0.3% |

| S110v | 2.8% | 9% | 14% | – | 3.5% | 3.5% | 2% |

Differences Between S110v And Maxamet

Both steels are best in different parameters and different conditions. There is a huge difference in the chemical composition of both steels.

The differences are:

- Maxamet is harder than the S110v.

- Maxamet has better edge retention and wear resistance than the S110v.

- Maxamet is not a stainless steel blade whereas S110v is a stainless steel blade.

- S110v has better toughness and corrosion resistivity than the Maxamet.

- S110v is much easier to sharpen and takes less time to sharpen than the Maxamet.

Conclusion: Which Steel Type Is Right For You Between S110v Vs Maxamet

Both the steel comes with some pros and cons, choose the one which has more features that you want.

S110v steel has a balance of all the properties. If you want a knife that has stainless steel properties, which are tough, highly corrosion resistant, and easy to sharpen then blindly choose S110v.

If you want hard steel having better edge retention properties, and high wear resistance then go with Maxamet.